How Hydraulic Cylinders Enhance Performance in Industrial Applications

In the realm of industrial machinery, efficiency and precision are paramount. One crucial component that plays a significant role in achieving these goals is the hydraulic cylinder.

These powerful devices are ubiquitous in a wide range of industrial applications, from manufacturing and construction to agriculture and aerospace.

In this blog post, we'll delve into the fascinating world of hydraulic cylinders in Australia and explore how they enhance performance in various industrial settings, revolutionising the way heavy-duty tasks are accomplished.

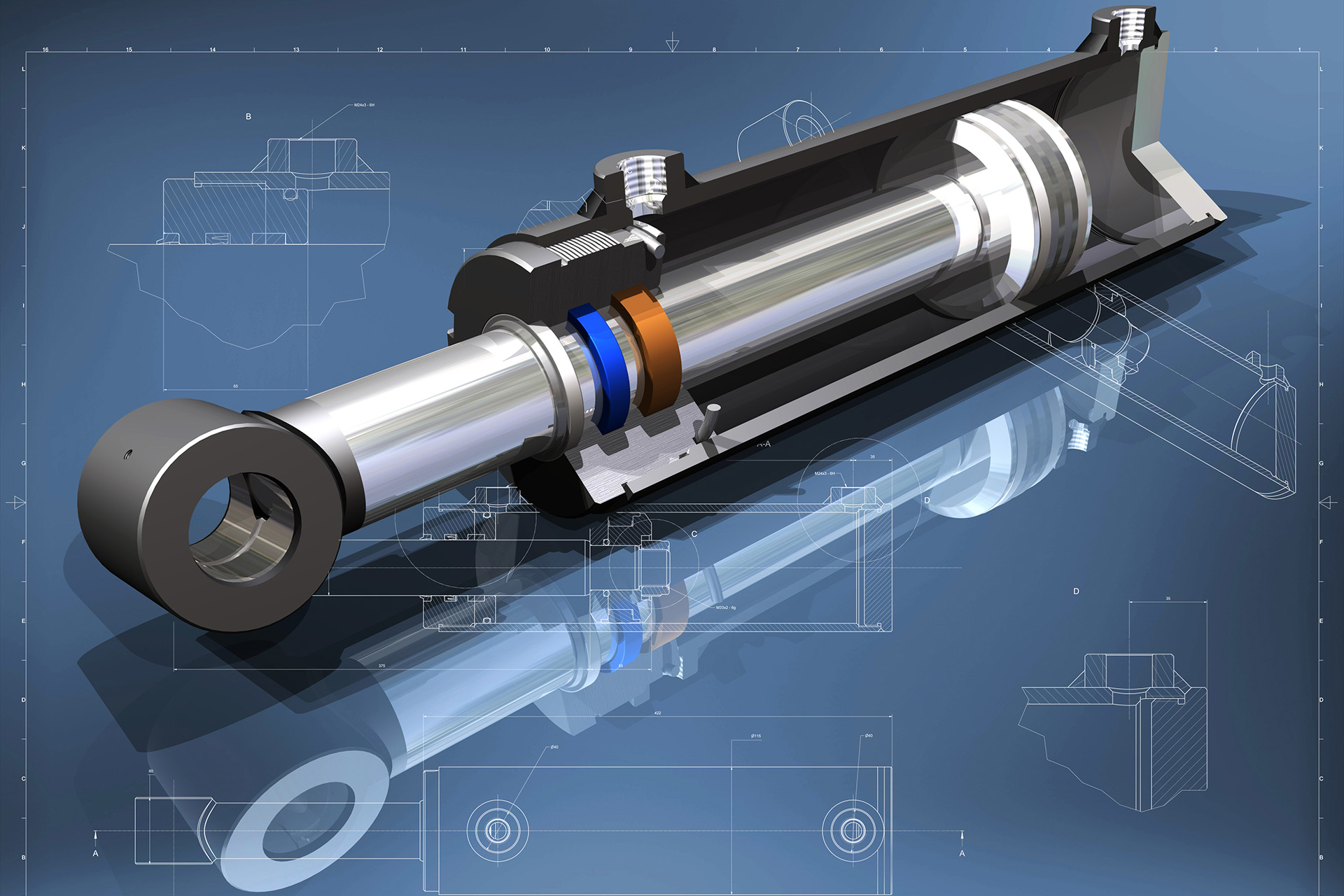

The Anatomy of Hydraulic Cylinders

At the heart of hydraulic systems, hydraulic cylinders are mechanical actuators that generate linear motion through the use of hydraulic fluid.

Comprising a cylindrical barrel, piston, rod, and various seals, these robust devices convert the energy from the pressurised fluid into force and motion, making them indispensable for countless industrial processes.

Precision and Control

One of the most significant advantages of hydraulic cylinders in Australia is the unparalleled precision and control they offer in industrial operations.

Whether it's lifting heavy loads, pushing, pulling, bending, or straightening materials, these cylinders provide smooth and controlled motion, allowing for finesse and accuracy in even the most demanding tasks.

This level of control is crucial in applications where consistency and precision are non-negotiable.

Power and Versatility

The power generated by hydraulic cylinders is truly awe-inspiring. With their ability to exert formidable force, these devices are capable of handling tasks that would be unattainable with other actuation methods.

From heavy lifting and pressing to powering machinery and equipment, their sheer strength makes them indispensable across diverse industrial sectors.

Furthermore, the versatility of these cylinders allows them to adapt to an array of challenging tasks, providing an adaptable and reliable solution in various environments.

Durability and Reliability

In the unforgiving landscape of industrial settings, equipment durability is crucial. Hydraulic cylinders are renowned for their robust construction and ability to withstand harsh conditions.

The materials used in their manufacture, coupled with meticulous engineering, result in devices that can endure high-temperature environments, heavy loads, and frequent operation without succumbing to wear and tear.

This durability translates into enhanced operational reliability, minimising downtime and maintenance costs.

Efficiency and Cost-Effectiveness

Efficiency is a cornerstone of industrial operations, and hydraulic cylinders excel in this regard.

By seamlessly converting hydraulic energy into mechanical force, these devices maximise energy utilisation, resulting in efficient and cost-effective performance.

Their exceptional power-to-size ratio and minimal energy loss during operation make them an economical choice for industrial applications, contributing to overall operational efficiency and reduced energy consumption.

Safety and Operator Well-Being

In industrial environments where heavy machinery and equipment are commonplace, safety is of paramount importance.

Hydraulic cylinders offer inherent safety advantages, such as stable and controlled motion, as well as overload protection features.

This not only safeguards the machinery and materials but also prioritises the well-being of operators and personnel working around these devices, further underscoring their significance in industrial settings.

Customisation and Adaptability

The adaptability of hydraulic cylinders is a key factor in their widespread use across diverse industrial applications.

Their design flexibility allows for customisation to suit specific operational requirements, whether it's modifying stroke length, bore diameter, or mounting options.

This adaptability ensures that the cylinders can seamlessly integrate into existing systems and machinery, enhancing their functionality without the need for costly overhauls.

Environmental Considerations

In an era where environmental sustainability holds increasing importance, hydraulic cylinders are making strides in minimising their ecological impact.

Innovations in seal technologies, fluid selection, and overall system design are driving advancements that reduce hydraulic fluid leakage and consumption, contributing to greener industrial practices.

Future Innovations and Advancements

As technology continues to evolve, so do hydraulic cylinders. Ongoing developments in materials, manufacturing techniques, and integration with smart technologies promise to further enhance the capabilities of these devices in the industrial landscape.

From predictive maintenance and condition monitoring to improved energy efficiency, the future of hydraulic cylinders looks promising, offering even greater potential for performance optimisation in industrial applications.

Conclusion

In conclusion, hydraulic cylinders in Australia stand as fundamental assets in the industrial realm, elevating the performance, safety, and efficiency of a myriad of applications.

Their precision, power, durability, efficiency, and adaptability make them indispensable across manufacturing, construction, agriculture, and beyond.

With an eye to sustainability and ongoing technological progress, these robust devices are not only instrumental today but also hold tremendous promise for the future of industrial machinery and equipment.

Source: How Hydraulic Cylinders Enhance Performance in Industrial Applications

Comments

Post a Comment